| Availability: | |

|---|---|

| Quantity: | |

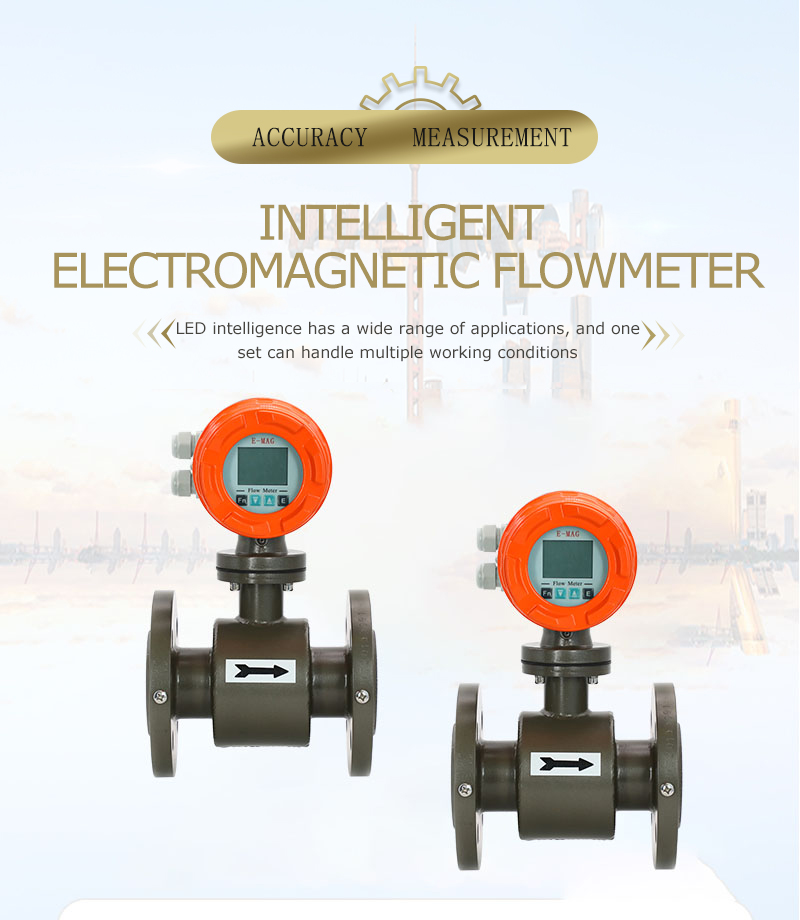

The measuring principle of electromagnetic flowmeter is based on the electromagnetic induction law of Farady. The sensor is mainly composed of measuring tube with isolate lining, a pair of electrodes installed by penetration of the measuring tube wall, a pair of coils and iron core to produce working magnetic field. When the conductive fluid flows through the measuring tube of the sensor, the voltage signal in direct proportion to the average flow velocity of the fluid will be inducted on the electrodes. The signal is amplified and treated by the transmitter to realize various display functions.

l Measurement is not affected by the variation of flow density, viscosity, temperature, pressure and conductivity. High accuracy measurement is guaranteed according to the linear measurement principle.

l No obstacle in the pipe, no pressure-loss and lower requirement for straight pipeline.

l DN15 to DN2000 covers a wide range of pipe size. A variety of liners and electrodes are available to satisfy different flow characteristic.

l Programmable low frequency square wave field excitation, improving measurement stability and reducing power consumption.

l Implementing 16 bits MCU, providing high integration and accuracy; Full-digital processing, high noise resistance and reliable measurement; Flow measurement range up to 150:1.

l High definition LCD display with backlight.

l RS485 or RS232 interface supports digital communication.

l Intelligent empty pipe detection and electrodes resistance measurement diagnosing empty pipe and electrodes contamination accurately.

l SMD component and surface mount technology (SMT) are implemented to improve the reliability.

Pipe size | DN10~DN3000mm |

Medium | conductive liquid,slurry |

Conductivity | ≥ 5 μS/cm |

Accuracy | ±0.5% |

Repeatability | ±0.1% |

Rated Pressure | 0.25, 0.6, 1.0, 1.6, 4.0MPa (or specified by customer) |

Display | Instantaneous flowrate, total flow, velocity, flowrate percentage with back light |

Signal output | 4~20mA current output, pulse output, RS-485, Hart, |

Power supply | 220VAC, 24VDC |

Convert type | Compact, remote |

Protection grade | IP65 (Compact) / IP68 (Remote) |

Explosion proof | Exia IIC T4 |

Velocity | 0.3 ~ 12m/s( 0.1 ~ 15m/s as required) |

Flowing direction | Forward, Reverse |

Electrode material | 316L, Pt, Ta, Ti, HB, HC, WC |

Electrode type | Standard fixed type, blade type |

Electrode numbers | 3 pcs |

Flange material | SS / CS |

Alarm(normal open) | Empty, excitation, upper / lower limit |

Ambient | -25 ~ +60℃, Humidity: 5 ~ 90% |

Communication | RS-485 / Hart |

The measuring principle of electromagnetic flowmeter is based on the electromagnetic induction law of Farady. The sensor is mainly composed of measuring tube with isolate lining, a pair of electrodes installed by penetration of the measuring tube wall, a pair of coils and iron core to produce working magnetic field. When the conductive fluid flows through the measuring tube of the sensor, the voltage signal in direct proportion to the average flow velocity of the fluid will be inducted on the electrodes. The signal is amplified and treated by the transmitter to realize various display functions.

l Measurement is not affected by the variation of flow density, viscosity, temperature, pressure and conductivity. High accuracy measurement is guaranteed according to the linear measurement principle.

l No obstacle in the pipe, no pressure-loss and lower requirement for straight pipeline.

l DN15 to DN2000 covers a wide range of pipe size. A variety of liners and electrodes are available to satisfy different flow characteristic.

l Programmable low frequency square wave field excitation, improving measurement stability and reducing power consumption.

l Implementing 16 bits MCU, providing high integration and accuracy; Full-digital processing, high noise resistance and reliable measurement; Flow measurement range up to 150:1.

l High definition LCD display with backlight.

l RS485 or RS232 interface supports digital communication.

l Intelligent empty pipe detection and electrodes resistance measurement diagnosing empty pipe and electrodes contamination accurately.

l SMD component and surface mount technology (SMT) are implemented to improve the reliability.

Pipe size | DN10~DN3000mm |

Medium | conductive liquid,slurry |

Conductivity | ≥ 5 μS/cm |

Accuracy | ±0.5% |

Repeatability | ±0.1% |

Rated Pressure | 0.25, 0.6, 1.0, 1.6, 4.0MPa (or specified by customer) |

Display | Instantaneous flowrate, total flow, velocity, flowrate percentage with back light |

Signal output | 4~20mA current output, pulse output, RS-485, Hart, |

Power supply | 220VAC, 24VDC |

Convert type | Compact, remote |

Protection grade | IP65 (Compact) / IP68 (Remote) |

Explosion proof | Exia IIC T4 |

Velocity | 0.3 ~ 12m/s( 0.1 ~ 15m/s as required) |

Flowing direction | Forward, Reverse |

Electrode material | 316L, Pt, Ta, Ti, HB, HC, WC |

Electrode type | Standard fixed type, blade type |

Electrode numbers | 3 pcs |

Flange material | SS / CS |

Alarm(normal open) | Empty, excitation, upper / lower limit |

Ambient | -25 ~ +60℃, Humidity: 5 ~ 90% |

Communication | RS-485 / Hart |