| Availability: | |

|---|---|

| Quantity: | |

1)No moving parts, high reliability

2) Wide range ratio 1:40

3) Low pressure loss

4) Vibration resistance and high temperature resistance

5) Suitable for DN15 toDN300

6) “L” shape head can be produced for easy assembly

| Executive standard | 《JB/T9249-2015》 Vortex flow meter |

| Nominal diameter (mm) | 15、20、25,32,40,50,65,80,100,125,150,200,250,300,(300~1000 plug-in) |

| Nominal Pressure (MPa) | DN15-DN200 4.0(>4.0 Supply agreement),DN250-DN300 1.6(>1.6Supply agreement) |

| Using Conditions | Operational temperature: Std:-40~100℃,KST-M:-40~250℃, KST-HC:-40~330℃;-40~400℃(special tailor-made) Environmental trmperature:-20℃~55℃,Relative humidity:5%~90%, |

| Material | Body:304(Other materials are supplied by agreement) Integrator housing:aluminium die casting |

| Allowable vibration acceleration | piezoelectric type:0.2g |

| Accuracy | ±1%R,±1.5%R;Plug-in:±2.5%R, |

| Rangeability | 1:6~1:30 |

| Supply voltage | sensor:DC +24V;transducer:DC +24V;battery-powered:3.6Vbattery |

| Output signal | Pluse output;4~20mA current, RS485(modbus- RTU agreement),Internet of Things GPRS and so on |

| Pressure loss factor | JB/T9249 standard Cd≤2.4 |

| Explosive-proof | The Ann model: Ex ia Ⅱ CT4 |

| IP Grade | IP65 |

| Counduit entry | Inside threadM20*1.5or other |

| Applicable medium | Gas,liquids ,steam |

| Transmission distance | Three-wire pulse output:≤300m,Two-wire standard current output (4~20mA) ≤1500m;load resistance≤500Ω; RS485≤1200m. |

Vortex flow meter covers a broad range of applications, measurement and control of overheated steam, saturated steam, compressed air and general gas( oxygen, Nitrogen, Hydrogen, natural gas, cooking gas, water and liquid (gasoline, alcohol, benzene,etc) .

In order to realize tight connection for small size pipes, threaded vortex flow meter is introduced into flow measurement and control. This type connection is suitable for pipe DN15~DN80.

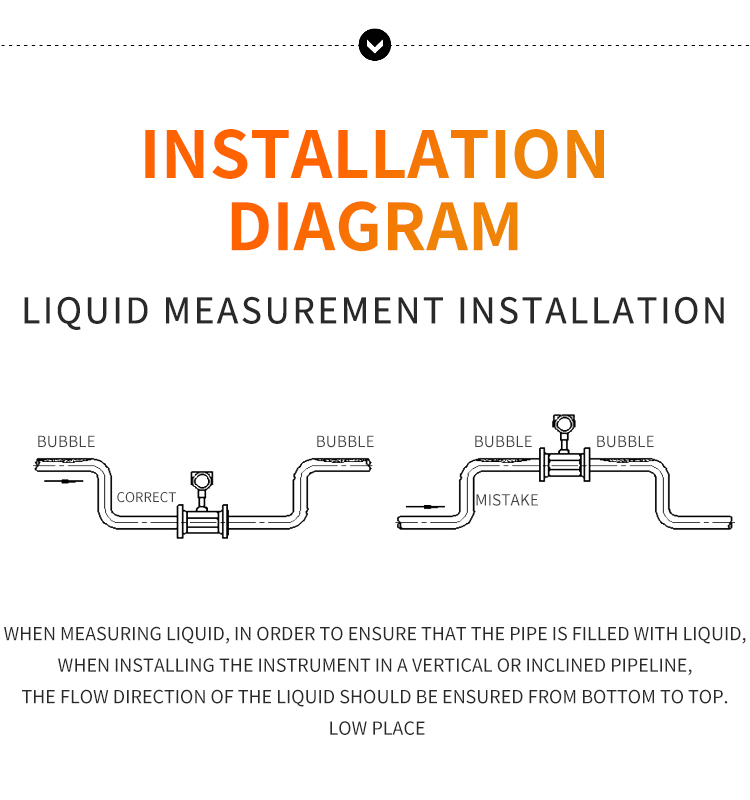

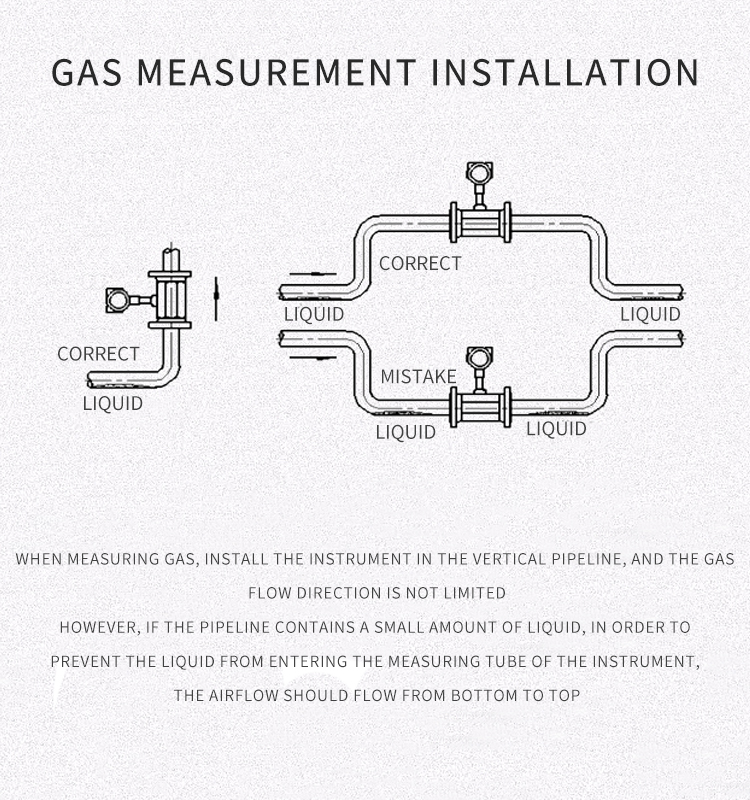

01Avoid strong current equipment, high frequency equipment, and strong switching power supply equipment as much as possible. The power supply of the meter should be separated from these devices as much as possible.

02Avoid the direct influence of high-temperature heat sources and radiation sources. If it must be installed, it must be insulated and ventilated.

03Avoid high humidity environment and strong corrosive gas environment. If it must be installed, it must be ventilated.

04Vortex flow meters should be installed on pipelines with strong vibration as far as possible. If installation is necessary, pipe fastening devices must be installed at the upstream and downstream 2D, and anti-vibration pads should be added to enhance the anti-vibration effect.

05The meter is best installed indoors. When installed outdoors, you should pay attention to waterproofing. Pay special attention to bending the cable into a U-shape at the electrical interface to prevent water from entering the amplifier housing along the cable.

06There should be ample space around the installation point of the instrument for installation of wiring and regular maintenance.

1)No moving parts, high reliability

2) Wide range ratio 1:40

3) Low pressure loss

4) Vibration resistance and high temperature resistance

5) Suitable for DN15 toDN300

6) “L” shape head can be produced for easy assembly

| Executive standard | 《JB/T9249-2015》 Vortex flow meter |

| Nominal diameter (mm) | 15、20、25,32,40,50,65,80,100,125,150,200,250,300,(300~1000 plug-in) |

| Nominal Pressure (MPa) | DN15-DN200 4.0(>4.0 Supply agreement),DN250-DN300 1.6(>1.6Supply agreement) |

| Using Conditions | Operational temperature: Std:-40~100℃,KST-M:-40~250℃, KST-HC:-40~330℃;-40~400℃(special tailor-made) Environmental trmperature:-20℃~55℃,Relative humidity:5%~90%, |

| Material | Body:304(Other materials are supplied by agreement) Integrator housing:aluminium die casting |

| Allowable vibration acceleration | piezoelectric type:0.2g |

| Accuracy | ±1%R,±1.5%R;Plug-in:±2.5%R, |

| Rangeability | 1:6~1:30 |

| Supply voltage | sensor:DC +24V;transducer:DC +24V;battery-powered:3.6Vbattery |

| Output signal | Pluse output;4~20mA current, RS485(modbus- RTU agreement),Internet of Things GPRS and so on |

| Pressure loss factor | JB/T9249 standard Cd≤2.4 |

| Explosive-proof | The Ann model: Ex ia Ⅱ CT4 |

| IP Grade | IP65 |

| Counduit entry | Inside threadM20*1.5or other |

| Applicable medium | Gas,liquids ,steam |

| Transmission distance | Three-wire pulse output:≤300m,Two-wire standard current output (4~20mA) ≤1500m;load resistance≤500Ω; RS485≤1200m. |

Vortex flow meter covers a broad range of applications, measurement and control of overheated steam, saturated steam, compressed air and general gas( oxygen, Nitrogen, Hydrogen, natural gas, cooking gas, water and liquid (gasoline, alcohol, benzene,etc) .

In order to realize tight connection for small size pipes, threaded vortex flow meter is introduced into flow measurement and control. This type connection is suitable for pipe DN15~DN80.

01Avoid strong current equipment, high frequency equipment, and strong switching power supply equipment as much as possible. The power supply of the meter should be separated from these devices as much as possible.

02Avoid the direct influence of high-temperature heat sources and radiation sources. If it must be installed, it must be insulated and ventilated.

03Avoid high humidity environment and strong corrosive gas environment. If it must be installed, it must be ventilated.

04Vortex flow meters should be installed on pipelines with strong vibration as far as possible. If installation is necessary, pipe fastening devices must be installed at the upstream and downstream 2D, and anti-vibration pads should be added to enhance the anti-vibration effect.

05The meter is best installed indoors. When installed outdoors, you should pay attention to waterproofing. Pay special attention to bending the cable into a U-shape at the electrical interface to prevent water from entering the amplifier housing along the cable.

06There should be ample space around the installation point of the instrument for installation of wiring and regular maintenance.