| Availability: | |

|---|---|

| Quantity: | |

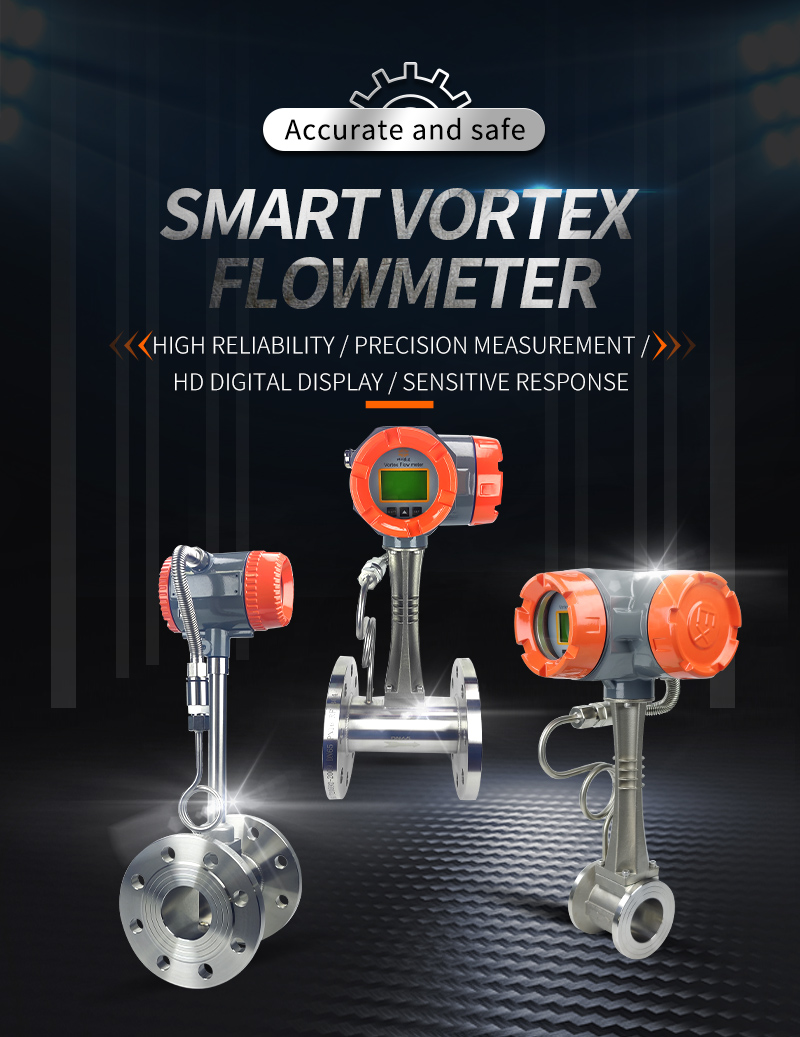

1) No moving parts,high reliability, long-term stability, simple structure and easy maintenance。

2) Various structural forms, flange , clamping, clamp in, threaded ,tri-clamp, also can be customized.

3) Wide measurement range and high accuracy, liquid is ±1.0%; gas is ±1.0~1.5%;

4) Pressure loss is small (about 1/4-1/2 of the orifice flowmeter), which belongs to the energy-saving flow meter.

Vortex flowmeter is a flow measurement instrument based on the vortex principle, which is suitable for the flow measurement of different media such as liquid and gas, and is widely used in petroleum, chemical industry, metering, water treatment, pharmaceutical, textile and other industries. The specific application scope is as follows:

1. Petroleum industry: Used for the measurement and control of oil, crude oil, natural gas and other fluids.

2. Chemical industry: suitable for the measurement and control of chemicals, solvents, liquefied gas, chemical raw materials and other fluids.

3. Water treatment industry: applicable to the measurement and control of tap water, hot water, cold water, industrial water and other water.

4. Pharmaceutical industry: suitable for the measurement and control of liquid medicine, beverage, pure water, injection and other fluids.

5. Textile industry: suitable for the measurement and control of yarn, silk, cotton and other textile raw materials.

Vortex flowmeters have the following advantages:

1. Wide measuring range: Vortex flowmeter is suitable for flow measurement of a variety of different media.

2. High measurement accuracy: The measurement accuracy of the vortex flowmeter is high, which can reach ±0.5%.

3. Good stability: vortex flowmeter has simple structure, long service life, and measurement accuracy is not affected by flow, density, viscosity and temperature and other factors, and good stability.

4. Convenient signal output: the signal output mode of the vortex flowmeter is diverse, which can output pulse frequency and analog signals.

Vortex flowmeter also has the following disadvantages:

1. Large pressure loss: The structure of the vortex flowmeter is more complex, and it will produce a certain pressure loss for low viscosity fluids.

2. High installation direction requirements: the installation direction of the vortex flowmeter is relatively high, if not installed correctly, it will affect the measurement accuracy.

3. The price is more expensive: vortex flowmeters are more expensive than other types of flowmeters.

Third, the selection of vortex flowmeter precautions

1. Flow range: According to actual needs, choose a suitable vortex flowmeter to avoid insufficient range or waste in the measurement process.

2. Measurement accuracy: Select the accuracy requirements of the vortex flowmeter according to actual needs, and avoid choosing products with too high or too low accuracy.

3. Measurement medium: When choosing vortex flow timing, you need to choose the product model according to the actual measurement medium to avoid choosing unsuitable products.

4. Installation requirements: The installation requirements of the vortex flowmeter are relatively high, and the appropriate installation method needs to be selected according to the actual situation to avoid the reduction of measurement accuracy caused by incorrect installation.

Vortex flowmeter is a commonly used flow measurement instrument, but there are often some failures in the process of use. This paper will introduce the common faults and treatment methods of vortex flowmeter.

1. The sensor is faulty

(1) The sensor signal is unstable: it may be caused by external interference or damage to the sensor. The treatment method is to check whether the connection between the sensor and the pipeline is firm, eliminate the source of interference, and carry out the necessary maintenance or replacement of the sensor.

(2)The sensor has no output signal: it may be caused by the sensor power supply failure, poor line contact or internal fault of the sensor. Check the power supply and cable connection, and repair or replace the faulty component.

2. Display failure

(1)The display cannot be displayed normally: it may be caused by the display damage or the display chip failure. Check the connection of the display and repair or replace the faulty component.

(2)The display value is abnormal: it may be caused by the display chip fault or parameter setting error. You can reset the parameters or replace the display.

1. Blockage of accumulation in the pipeline: blockage caused by long-term accumulation in the pipeline without cleaning. The treatment method is to clean the pipeline regularly to keep the pipeline unblocked.

2. The sensor is blocked: The measurement is inaccurate because the sensor is partially blocked by solid particles in the fluid. The treatment method is to clean the sensor and take appropriate measures to prevent the blockage again.

4. Power supply failure

(1) Power supply failure: The fault may be caused by power supply damage or poor contact with the power line. Check the power supply and cable connection, and repair or replace the faulty component.

(2)Insufficient battery power: When using battery power supply, insufficient battery power will also cause the vortex flowmeter to not work properly. The treatment method is to replace the battery or charge it in time.

5. Temperature effect

(1)The ambient temperature is too high: When the working ambient temperature of the vortex flowmeter exceeds the allowable range, its performance may be affected. The treatment method is to take cooling measures to ensure that the flow meter works within the normal temperature range.

(2)The fluid temperature is too high: When the fluid temperature exceeds the rated temperature range of the vortex flowmeter, the measurement results may be distorted. The treatment method is to take cooling measures to ensure that the fluid temperature is within the rated range of the vortex flowmeter.

6. Other faults

Electromagnetic interference: Vortex flowmeter is susceptible to electromagnetic interference, resulting in inaccurate measurement. The solution is to eliminate the interference source and take shielding measures.

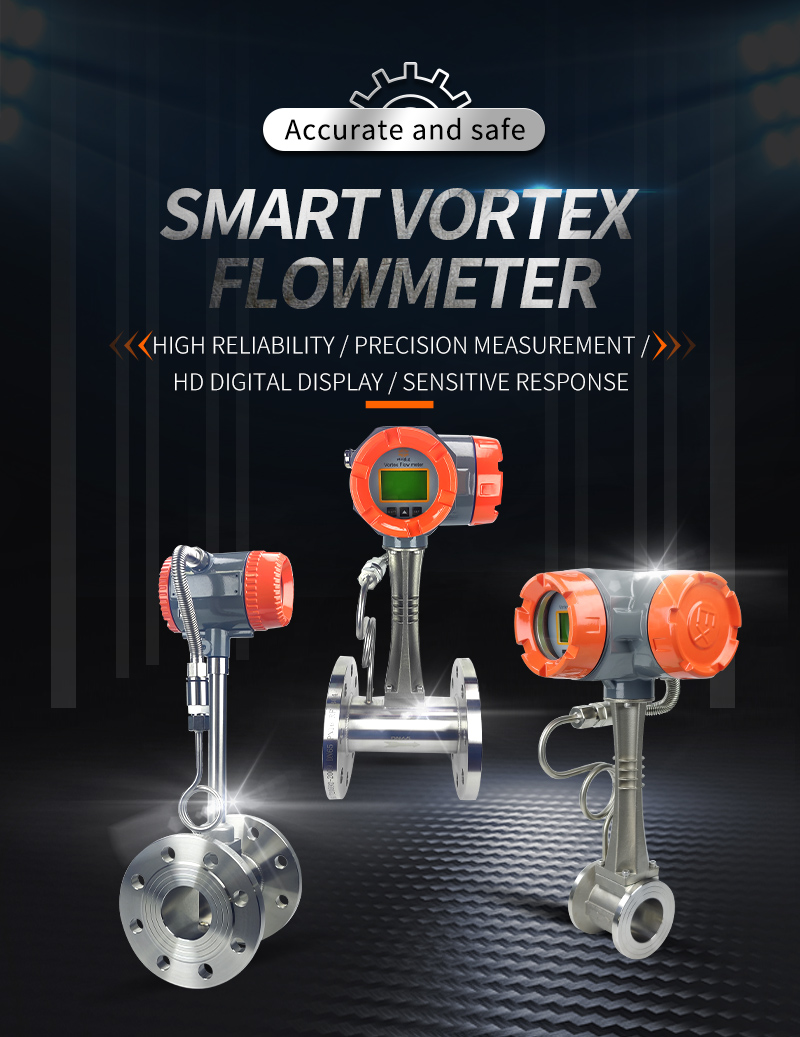

1) No moving parts,high reliability, long-term stability, simple structure and easy maintenance。

2) Various structural forms, flange , clamping, clamp in, threaded ,tri-clamp, also can be customized.

3) Wide measurement range and high accuracy, liquid is ±1.0%; gas is ±1.0~1.5%;

4) Pressure loss is small (about 1/4-1/2 of the orifice flowmeter), which belongs to the energy-saving flow meter.

Vortex flowmeter is a flow measurement instrument based on the vortex principle, which is suitable for the flow measurement of different media such as liquid and gas, and is widely used in petroleum, chemical industry, metering, water treatment, pharmaceutical, textile and other industries. The specific application scope is as follows:

1. Petroleum industry: Used for the measurement and control of oil, crude oil, natural gas and other fluids.

2. Chemical industry: suitable for the measurement and control of chemicals, solvents, liquefied gas, chemical raw materials and other fluids.

3. Water treatment industry: applicable to the measurement and control of tap water, hot water, cold water, industrial water and other water.

4. Pharmaceutical industry: suitable for the measurement and control of liquid medicine, beverage, pure water, injection and other fluids.

5. Textile industry: suitable for the measurement and control of yarn, silk, cotton and other textile raw materials.

Vortex flowmeters have the following advantages:

1. Wide measuring range: Vortex flowmeter is suitable for flow measurement of a variety of different media.

2. High measurement accuracy: The measurement accuracy of the vortex flowmeter is high, which can reach ±0.5%.

3. Good stability: vortex flowmeter has simple structure, long service life, and measurement accuracy is not affected by flow, density, viscosity and temperature and other factors, and good stability.

4. Convenient signal output: the signal output mode of the vortex flowmeter is diverse, which can output pulse frequency and analog signals.

Vortex flowmeter also has the following disadvantages:

1. Large pressure loss: The structure of the vortex flowmeter is more complex, and it will produce a certain pressure loss for low viscosity fluids.

2. High installation direction requirements: the installation direction of the vortex flowmeter is relatively high, if not installed correctly, it will affect the measurement accuracy.

3. The price is more expensive: vortex flowmeters are more expensive than other types of flowmeters.

Third, the selection of vortex flowmeter precautions

1. Flow range: According to actual needs, choose a suitable vortex flowmeter to avoid insufficient range or waste in the measurement process.

2. Measurement accuracy: Select the accuracy requirements of the vortex flowmeter according to actual needs, and avoid choosing products with too high or too low accuracy.

3. Measurement medium: When choosing vortex flow timing, you need to choose the product model according to the actual measurement medium to avoid choosing unsuitable products.

4. Installation requirements: The installation requirements of the vortex flowmeter are relatively high, and the appropriate installation method needs to be selected according to the actual situation to avoid the reduction of measurement accuracy caused by incorrect installation.

Vortex flowmeter is a commonly used flow measurement instrument, but there are often some failures in the process of use. This paper will introduce the common faults and treatment methods of vortex flowmeter.

1. The sensor is faulty

(1) The sensor signal is unstable: it may be caused by external interference or damage to the sensor. The treatment method is to check whether the connection between the sensor and the pipeline is firm, eliminate the source of interference, and carry out the necessary maintenance or replacement of the sensor.

(2)The sensor has no output signal: it may be caused by the sensor power supply failure, poor line contact or internal fault of the sensor. Check the power supply and cable connection, and repair or replace the faulty component.

2. Display failure

(1)The display cannot be displayed normally: it may be caused by the display damage or the display chip failure. Check the connection of the display and repair or replace the faulty component.

(2)The display value is abnormal: it may be caused by the display chip fault or parameter setting error. You can reset the parameters or replace the display.

1. Blockage of accumulation in the pipeline: blockage caused by long-term accumulation in the pipeline without cleaning. The treatment method is to clean the pipeline regularly to keep the pipeline unblocked.

2. The sensor is blocked: The measurement is inaccurate because the sensor is partially blocked by solid particles in the fluid. The treatment method is to clean the sensor and take appropriate measures to prevent the blockage again.

4. Power supply failure

(1) Power supply failure: The fault may be caused by power supply damage or poor contact with the power line. Check the power supply and cable connection, and repair or replace the faulty component.

(2)Insufficient battery power: When using battery power supply, insufficient battery power will also cause the vortex flowmeter to not work properly. The treatment method is to replace the battery or charge it in time.

5. Temperature effect

(1)The ambient temperature is too high: When the working ambient temperature of the vortex flowmeter exceeds the allowable range, its performance may be affected. The treatment method is to take cooling measures to ensure that the flow meter works within the normal temperature range.

(2)The fluid temperature is too high: When the fluid temperature exceeds the rated temperature range of the vortex flowmeter, the measurement results may be distorted. The treatment method is to take cooling measures to ensure that the fluid temperature is within the rated range of the vortex flowmeter.

6. Other faults

Electromagnetic interference: Vortex flowmeter is susceptible to electromagnetic interference, resulting in inaccurate measurement. The solution is to eliminate the interference source and take shielding measures.